5th December 2018

Ice Age Rope Castles

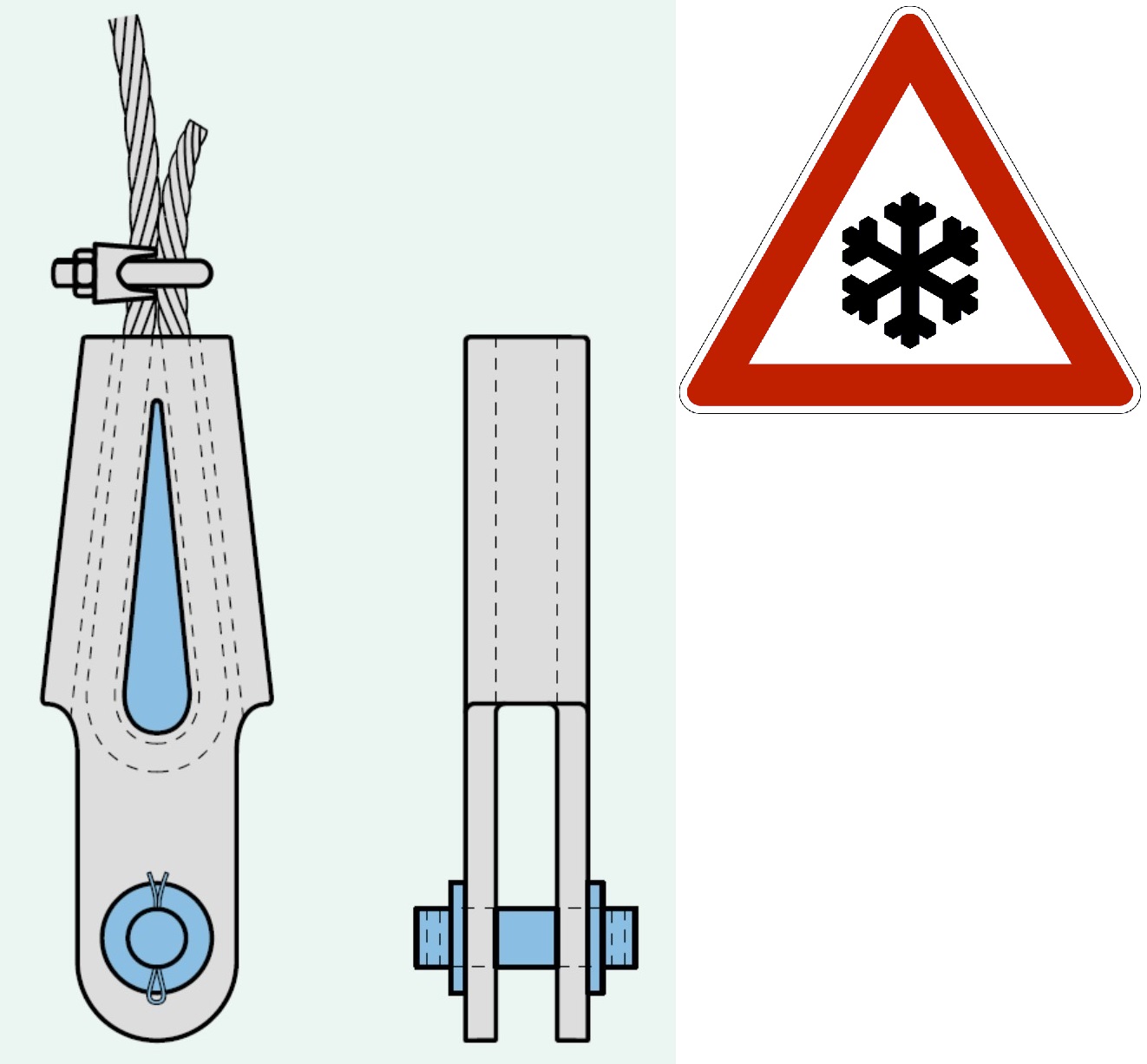

In the mountains, the summer of a century has swiftly made way to the onset of winter. Snowcats and aerial passenger lines will soon be everywhere. This means that materials have to be extra resilient. In regard to mountain railway technology, the materials used for classic rope end connectors have to be sufficiently tough, even at -40°C. This includes railway and support cable sockets as well as aluminium-pressed thimbles on anchoring cables. If the length of the respective cables has to be adjusted or retightened, thimbles and cotter would frequently make sense as an end connector. However, you should be careful in case of low temperatures.

Many conventional thimbles and cotters do not guarantee the impact value needed in practice in case of temperatures below -20°C. As there is a lack in ductility, there is a risk that these materials may not be able to withstand the pulsating strains of railcar operations and environmental influences and that cracks may appear. If using materials, which are particularly suited for temperatures of -40°C, their behaviour may deviate from usual performance indicators at normal temperatures.

HABEGGER Maschinenfabrik AG and JAKOB Rope System AG have therefore tested thimbles and cotters made from alternative materials with optimum low temperature characteristics by means of a classic fatigue test as per EN 13411. Following 75,000 loads between 15% and 30% of the rope’s minimum breaking force, the components did not show any signs of interference. Even during the subsequent tension tests, all security requirements in regard to the rope and its end connectors were fully met.

It is therefore possible to switch to suitable materials. The rope and hoisting technology experts at HABEGGER and JAKOB would of course be happy to answer any questions you may have in regard to existing rope end connectors. Please feel free to give us a call.