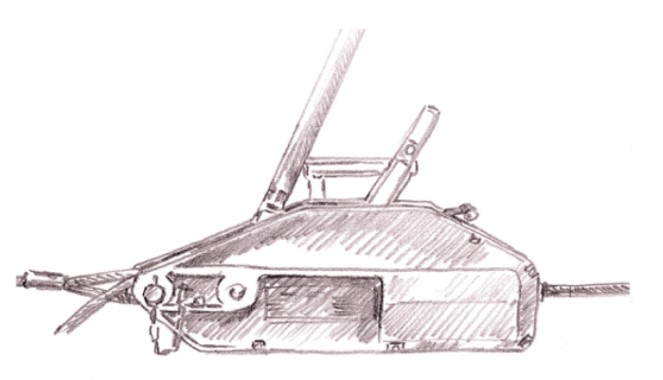

Functional principle of HABEGGER

|

|

All HIT wire rope hoists are based on the same functional principle: A wire rope of any length is guided through two pairs of clamping jaws in a straight line. When the drive lever is moved back and forth, the wire is moved forwards or backwards (according to the selection) smoothly and without slippage. An ingenious lever mechanism means that one pair of clamping jaws opens and pulls in more wire, while the other remains closed. This opening and closing is repeated alternately. Both clamping jaws automatically close under load. The clamping pressure increases in proportion to the tensile load. Safety The superior safety offered by HABEGGER wire rope hoists is achieved by the interplay of many details: ingeniously simple design, highstrength heat-treated materials as well as an overload protection system. The locking pin on the actuation lever shears off if the load reaches one-and-a-half times the rated force. The load can still be lowered, however. Quality guarantee Painstaking quality checks and material tests are the norm in our factory. Public authorities and official testing institutes are becoming increasingly concerned with quality and safety. Our products pass even the harshest tests with flying colours. Certificates from the TÜV and UL, to name only the most important ones, give you a copper-bottomed guarantee for the top quality of HABEGGER wire rope hoists. Our warranty extends to 5 years. Consulting With HABEGGER wire rope hoists, it is often possible to achieve even unusual applications. Therefore, please don’t hesitate to call for our advice if you happen to be faced with a problematic application. |

|

|

|